This custom BMW R75/5 dominates the Handmade Show

it takes a a lot of faith to delegate your custom motorcycle project to someone else—and then give them full control over it. But if you find the right people to work with, the results can be spectacular. That’s the story behind this custom BMW R75/5, it turned out so great that we awarded it the ‘Best’ choice at this year’s competition. Manual display.

It belongs to Helmut Siepmann, a product designer near Toronto, Canada. Sponsor’s bike, 1971 BMW R75/5, is a real granary found, completely rusted, upholstery broken and parts missing. Helmut planned to revive it and turn it into a cafe racer.

Needing help with the tough parts, Helmut turned to his friend, Johnny Lorette, a retired tool and mold maker. Helmut tells us: “Johnny works on exciting custom bike and car projects in the best-equipped two-car garage north of the US border, under the label 1755 Customs. “There is no website and no phone number—but there is certainly a waiting list.”

“He was excited and offered to help, but before long he simply took over the project entirely. Johnny said, ‘There won’t be cafe racer, just leave it to me.’ So that’s what I did – no regrets.”

Johnny’s idea was to modernize some aspects of the BMW R75/5, while also incorporating some of the features that predated the boxers of the 1970s. Key features of the original bike, like the drum brakes. drums, shaft drive and iconic headlights, have all been preserved as a mark of its origins. Helmut added: “There is nothing on the table.

Johnny went deep into this motorcyclists; so deep that the work took two and a half years and 1,400 man hours to complete. “There is never a rush or a sense of urgency, and everything is done with focused and precise planning. If something isn’t quite right, we’ll do it again.”

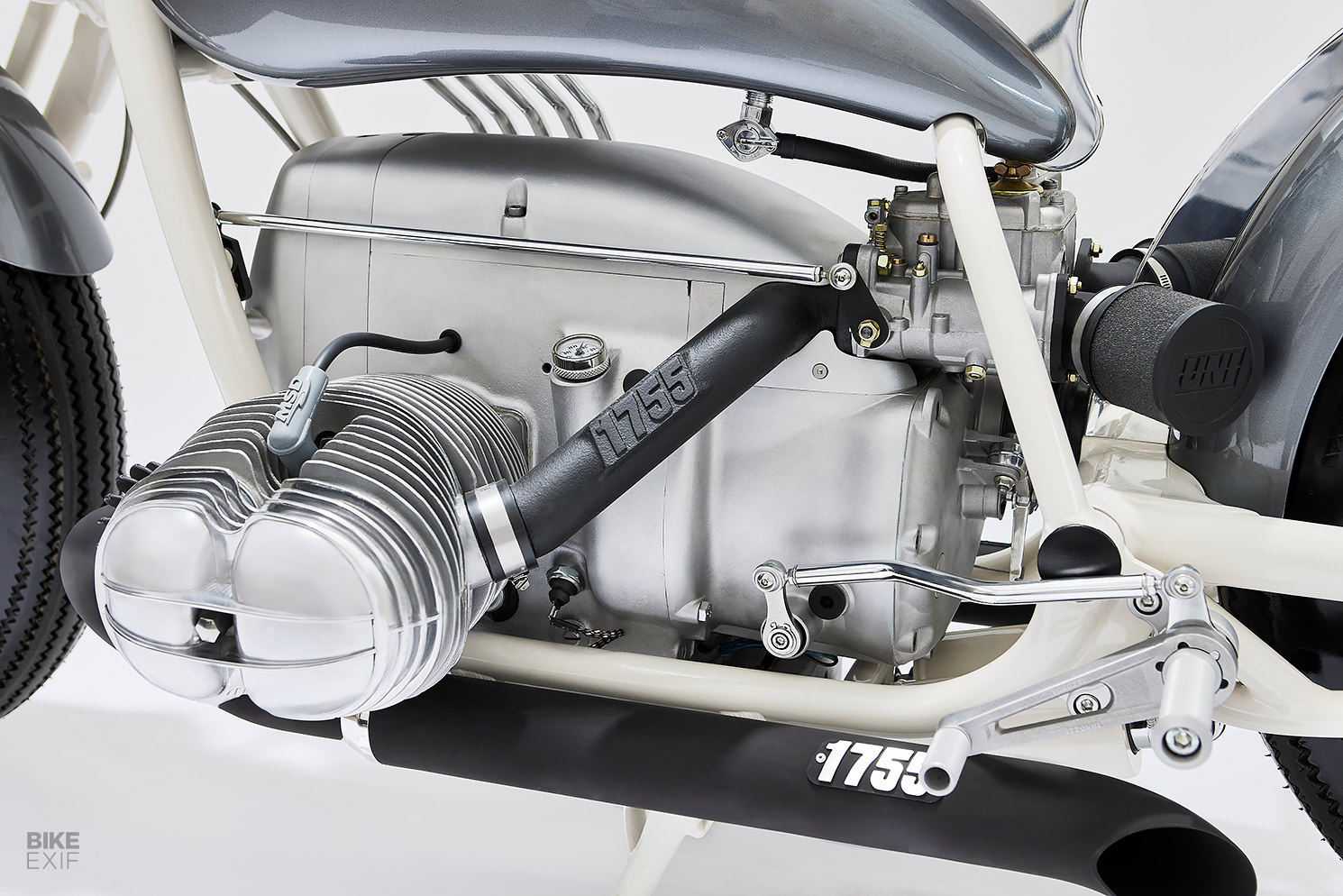

Keeping this ethos, Helmut sent the powertrain to BMW Air Assist for a factory spec overhaul. The engine returns with reworked cylinders, Mahle pistons, overhauled heads with new guides, valves and springs, and new washers, rings and bearings. The transmission and drive shaft were also refurbished and the clutch was brand new.

Gone are the OEM Bing carburetors. Instead, 3D printed intake manifolds connect the ends to a twin Weber carburetor, powered by Uni foam filters. Since the carburetor is much further back, the throttle now pulls a custom link to activate it.

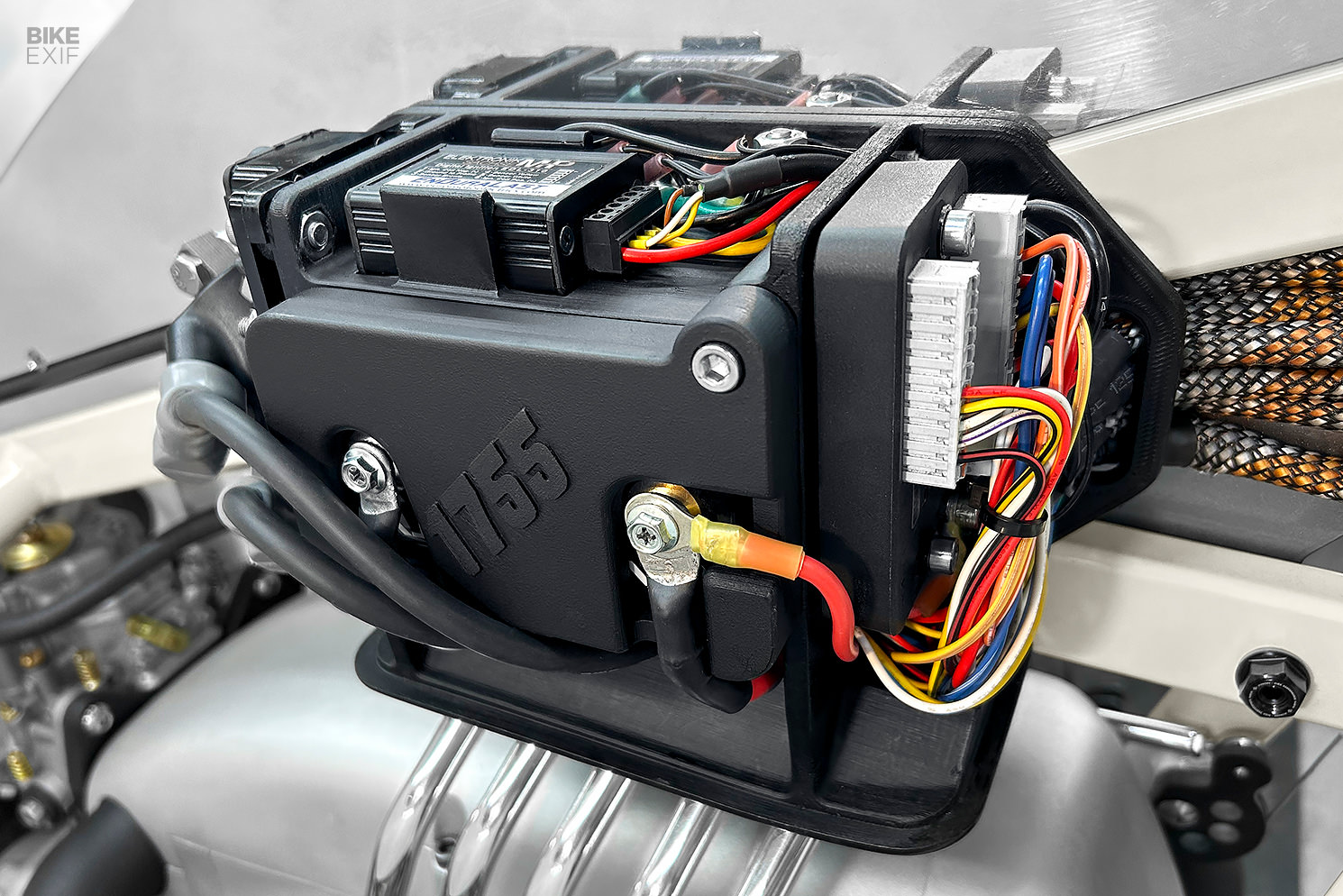

Moving on to electronics, Johnny installed a new Bosch unit, along with an aftermarket regulator/rectifier and a Motogadget mo.unit controller. The ignition system has been upgraded to a new one from Euro MotoElectrics. But the way the electronics are packaged is what’s impressive.

Johnny built a split gas tank for the BMW; the left carries the fuel, while the right includes the electronics. Beneath it, a 3D-printed box holds every last component, including the battery, with a haunting degree of neatness. Aluminum tubes carry the wires associated with the engines, eliminating the tangle of wires that often take up this space on older aircraft locomotives.

Running between the two halves of the gas tank is a CNC machined structure that Helmut calls ‘The Fish’. It not only acts as a holder for the half tank and saddle, but also as a structural member of the chassis. And it hides the wiring that runs to the taillights, which are embedded under the rear of the saddle.

The saddle rests on a hand-punched aluminum base, with a special mechanism to pop the cover off when you need to reach the taillights’ wiring or bulbs. Helmut adds: “It is not coincidental that it is somewhat similar to a bicycle saddle. “Johnny is known for his contributions to cross-country and downhill cycling, which he designed and built for Ruthless Cycles.”

Further back, a spacious rear fender hugs the rear wheel, mounted on a custom rack that complements the ‘Fish’ design. Neither the fender brace nor the saddle mount have any visible laces, giving the entire rear end a surreal, floating feel.

Needless to say, achieving this look also means eliminating OEM shocks. Johnny installed a pair of drag-type shock absorbers in their stead, hiding them under the engine. Then he braced the swingarm to compensate for the new load angle.

The front suspension has been swapped for a spring-loaded front end, with some notable modifications. Johnny shortened the springs to make the fork in the handlebars more compact, then built the headlight brackets and fenders to keep things neater. The BMW steering head also needed a significant rework to accommodate the spring setup.

The original headlight sits on top, fitted with a Legendary Motorcycles GPS-enabled tachometer. The cockpit also features a handcrafted set of direct-mount bars, fitted with state-of-the-art switches, mirrors and turn signals at the end of the Motogadget bar. Small exposed wiring is encased in fabric conduit, with color matching subtle brass accents strewn throughout the building.

Even the wheels have a long list of mods. At a glance, they’re classic 18-inch Boranni rims, wrapped in Firestone rubber. However, the front hub has a custom brake cooling scoop and air vents with 3D printed flaps.

Both wheels also run with custom axles, bearings and spacers. The front wheel needs those modifications to work with the spring fork, but the rear end is simply made to match the diameter of the front wheel. In fact, the rear hub assembly still uses the original BMW axle inside, with hidden wires running to the lights on a custom license plate holder.

Completing the spec sheet is a custom exhaust system, mounted as close to the frame as possible. In fact, Johnny stuffed it so tightly that he had to make holes in the back of each muffler to make room for the engine mounting bolts. A CNC machined aluminum badge adorns each end of the can.

Complete with an elegant color scheme, Helmut’s custom BMW R75/5 is flawless. It’s been a minute since we saw it live, but we’re still trying to get it out of our heads.

Image of Mark Luciani