How golf balls inspire dimpled pistons for diesel engines

The future of heavy-duty diesel trucks may not be as bleak as some have predicted.

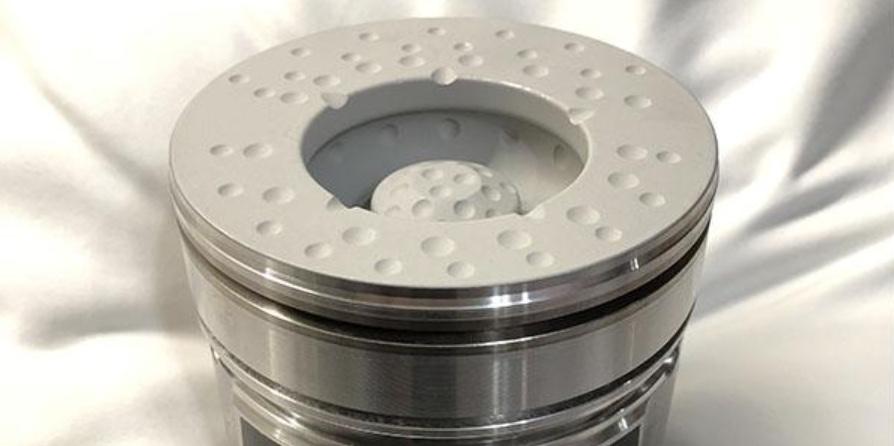

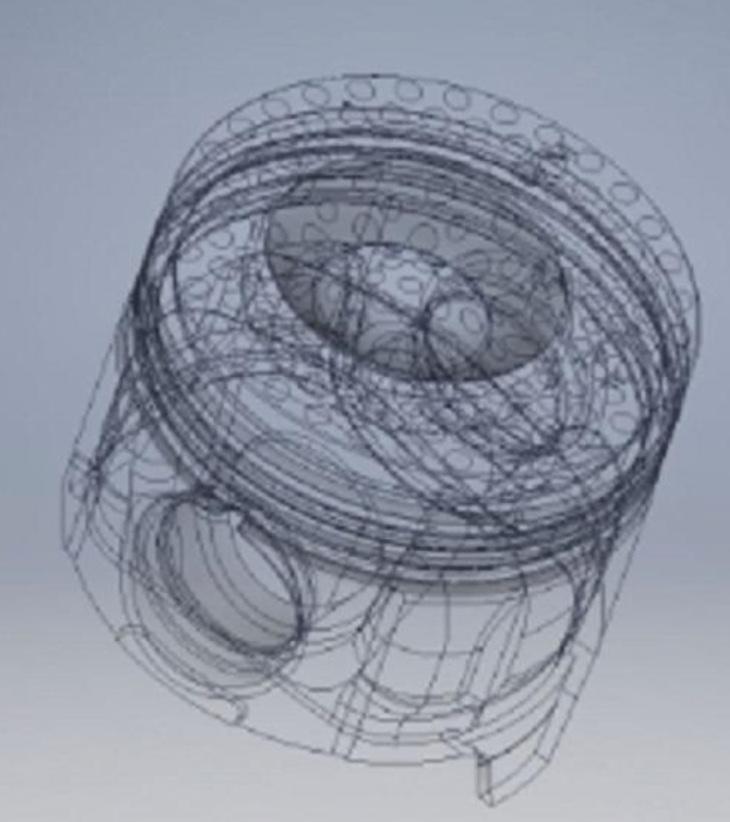

With the introduction of recessed pistons, truck owners can now enjoy increased power, reduced fuel consumption and reduced particulate matter emissions. The technology behind these pistons is fascinating, with the golf ball-like indentation creating a tight boundary layer in the combustion chamber, keeping the air and fuel suspended for longer.

This results in more complete combustion, reduced carbon build-up and minimized emissions.

Speed of Air (SoA) is at the forefront of this technology, having conducted extensive testing to develop these pistons. They used different flow gauge techniques to identify the fuel wash areas on top of the pistons indicated by excess carbon buildup.

They tried many other texturing techniques before solving the golf ball-like indentation problem, which proved to be the most effective at keeping the air-fuel mixture in suspension. longer.

Furthermore, SoA’s piston design includes pressure relief slots machined into the tops of the pistons, which reduces pressure in the bowl area and accelerates the combustion of the fuel-air mixture. .

This results in a quieter engine when compared to the OE piston design.

Independent test results are impressive. The Caterpillar 3516 engine used in the 793D mining truck for Newmont North America has been reworked with the SoA pistons being the only change from the normal parts of the reworked engine.

The engine had gone from 16.30 hours per day on Cat pistons to 18.34 hours per day on SoA pistons by the time it was taken apart for servicing again in 2017 after 915 date.

Cylinder, piston, ring and liners packages show significant useful life remaining, and carbon build-up on pistons and crankcase deposits is very low compared to manufacturing runs. on the other hand are the key findings in the report. Emissions also show significant reductions and improvements over the “comparison engine”.

In another test conducted by Olsen Eco Laboratories in Fullerton, California, the original 5.9-liter Cummins engine was compared to an engine fitted with a single set of SoA pistons. The report shows a 15.5% increase in horsepower and 15.2% increase in torque.

These results are important and demonstrate the potential of this technology in revolutionizing the diesel-powered heavy-duty truck industry.

So what does the future hold for heavy duty diesel trucks? While the world is moving towards electric vehicles, there is still a significant need for heavy duty diesel trucks for those who do heavy lifting or want to look like them.

With the introduction of concave pistons, heavy duty diesel trucks can now increase capacity, reduce fuel consumption and minimize particulate emissions.

The technology behind these pistons is fascinating, and companies like SoA are at the forefront of developing this technology.