Towards Customizable, Lab-Growed Wood – Are You Excited?

The researchers show they can control the properties of plant materials grown in the lab, which could allow the production of wood products with less waste.

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

CREDIT: COURT OF IMAGES OF LUIS FERNANDO VELÁSQUEZ-GARCÍA, ASHLEY BECKWITH, ET AL

Every year, the world loses about 10 million hectares of forests – an area the size of Iceland – to deforestation. At that rate, some scientists predict the world’s forests could disappear in 100 to 200 years.

In an effort to provide an eco-friendly and low-waste alternative, researchers at MIT have pioneered the tuning technique to create wood-like plant material in the lab, which could allow someone to “grow” a wooden product like a table without having to cut down trees, treat the wood, etc.

These researchers have now demonstrated that, by tweaking certain chemicals used in the growth process, they can precisely control the physical and mechanical properties of plant materials, such as such as its hardness and density.

They also show that, using 3D bioprinting, they can grow plant material in shapes, sizes and forms that are not found in nature and cannot be easily produced using conventional methods. traditional agriculture.

“The idea is that you can grow these plant materials in exactly the shape you need, so you don’t have to do any crafting but this cuts down on energy and waste. There is a lot of potential to extend this and develop three-dimensional structures,” said lead author Ashley Beckwith, a PhD graduate.

Although still in its early days, this study demonstrates that plant materials grown in the lab can be tailored to have specific properties, which may one day allow researchers to develops wood products with the exact features needed for a particular application, such as high strength to support walls senior author Luis Fernando Velásquez-García, a principal scientist at the Chamber MIT’s Microsystems Technology experiment, explained.

Joining Beckwith and Velásquez-García on the paper is Jeffrey Borenstein, a biomedical engineer and team leader at Charles Stark Draper Laboratories. The study was published today in Materials Today.

Planting cells

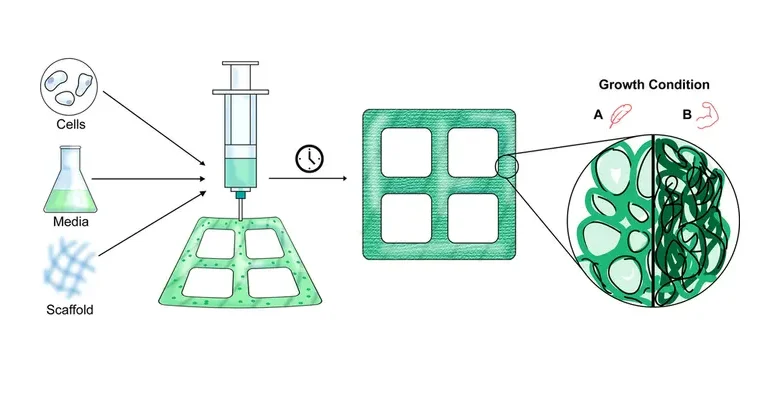

To begin the process of growing plant material in the lab, the researchers first isolated cells from young leaves. Zinnia elegans tree. The cells were cultured in liquid medium for two days, then transferred to a gel medium, containing nutrients and two different hormones.

Regulating hormone levels at this stage in the process allows researchers to tune the physical and mechanical properties of plant cells growing in that nutrient-rich environment.

“In the human body, you have hormones that determine how your cells grow and how certain characteristics appear. In the same way, by varying the hormone levels in the nutrient medium, plant cells respond differently. Just by manipulating these tiny amounts of chemistry, we can make quite large changes in terms of physical results,” says Beckwith.

In a way, these growing plant cells behave almost like stem cells — researchers can give them signals to tell them what they will become, Velásquez-García says. know more.

They used a 3D printer to extrude the cell culture gel solution into a specific structure in a petri dish, and let it incubate in the dark for three months. Even with this incubation period, the researchers said, the process was about two orders of magnitude faster than the time it takes for a plant to develop to maturity.

After incubation, the resulting cell-based material is dehydrated, and then the researchers evaluate its properties.

Wood-like characteristics

They found that lower hormone levels resulted in the growth of plant material with round, open cells of lower density, while higher hormone levels resulted in the growth of structured plant material. Smaller, denser cells. Higher hormone levels also produce harder plant material; The researchers were able to grow plant material with a storage modulus (stiffness) similar to that of some natural woods.

Another goal of this work was to study the so-called evaporative process in these laboratory-grown plant materials. Lignin is a polymer that is deposited in the cell walls of plants, making them hard and woody. They found that higher hormone concentrations in the growing medium caused more evaporation, resulting in the plant material having more wood-like properties.

The researchers also demonstrate that, using a 3D bioprinting process, plant materials can be grown in custom shapes and sizes. Instead of using a mold, the process involves the use of a customizable computer-aided design file that is fed into a 3D bioprinter, which deposits the cell gel culture into a shape. Specifically. For example, they can grow plant material in the form of a tiny evergreen tree.

Borenstein says this kind of research is relatively new.

He adds: “This work demonstrates the power that an interface between engineering and biology can bring to address an environmental challenge, leveraging advances originally developed for healthcare applications.

The researchers also showed that cultured cells can survive and continue to grow for many months after printing, and that using thicker gels to create a thicker structure of plant material had no effect. on the survival rate of cells grown in the laboratory.

“Customizable”

“I think the real opportunity here is to optimize what you use and how you use it. If you want to create an object that serves some purpose, then mechanical expectations need to be considered. Velásquez-García says the process is truly customizable.

Now that they have demonstrated the controllability of this technique, the researchers want to continue testing so they can better understand and control cell growth. They also wanted to explore how other chemical and genetic factors might direct cell growth.

They hope to evaluate whether their method can be ported to a new species. Zinnia trees do not produce wood, but if this method were to be used to create a commercially important tree species, such as pine, the process would need to be adapted for that species, Velásquez-García speak.

Ultimately, he hopes this work can help spur other groups to join this area of research to help reduce deforestation.

“Trees and forests are a wonderful tool to help us manage climate change, so using these resources as strategically as possible will be a future societal necessity, ” Beckwith adds.

This research was funded in part by the Draper Scholars Program.

###

Written by Adam Zewe, MIT News Office

Additional background

Paper: “Physical, mechanical, and microstructural characterization of novel, 3D-printable, tunable, laboratory-grown plant materials generated from Zinnia elegans cell cultures”

https://www.sciasedirect.com/science/article/pii/S1369702122000451

JOURNEYS

Materials Today

DOI

10.1016 / j.mattod.2022.02.012

ARTICLE TITLE

“Physical, mechanical, and microstructural properties of novel, 3D-printable, tunable, laboratory-grown plant material, generated from Zinnia elegans cell cultures”