Rimac Nevera crash test: Nine 1,914 hp supercars destroyed

Fitting a car to meet different safety rules for different markets is a time-consuming and very expensive proposition. For Rimac Nevera, 1,914 hp electric motor supercarThat process took four years, a statement released by the company said.

Billed as fastest accelerating car in the world, the Nevera accelerates from 0 to 60 in just 1.85 seconds and reaches a top speed of 258 mph. It’s pasted at €2 million ($2.27 million), so crash test not be disregarded.

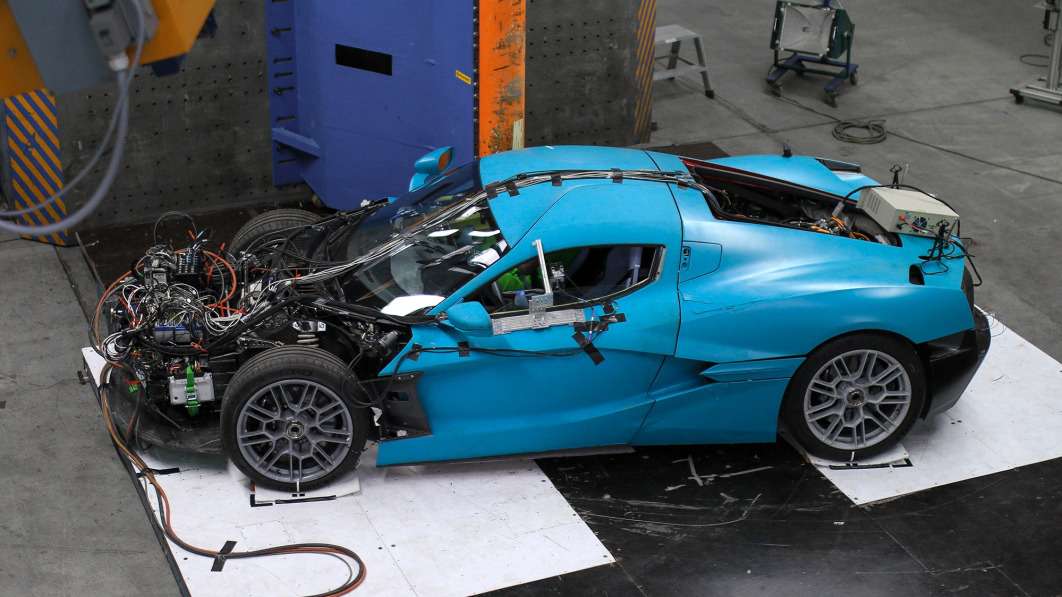

Rimac says that the Nevera prototypes were put into the vibrator with 45 physical impact tests and destroyed nine of them. If you’re watching, that’s over $20 million for the smashed Rimacs.

Fortunately, for more passive safety tests, computer simulations can be used instead. Rimac says engineers have conducted thousands of digital tests using High-performance cluster computer Very detailed simulation. Rimac says a physical test can take as little as 80 milliseconds, but a single HPCC simulation can take up to 20 hours of processing time.

The simulations have also proved useful in letting engineers know what kind of adjustments are needed for the actual crash test cars to pass. Then they make those changes to car design before, as Rimac said, “theme[ing] them to the ‘wall’. “

While European crash testing was completed last year, final testing for US certification took place in January. The test in question mimicked a 20 mph lateral impact with a pole, to simulate the action of sliding against a lamp post or tree (this appears to be a it’s all the same shared destiny because the supercar). This is a difficult test, as it hits a car in a place where there are very few cars – and therefore very little space for energy-absorbing shrinkage zones – between the stationary object and the occupants. car.

However, the company says that Nevara works quite well – in fact, very well, The door closest to the collision can still be opened after the crash. The fact that the Nevara is constructed from a carbon fiber monocoque – largest single carbon fiber used on cars – ranges from front to rear suspension. Rimac says that makes Nevara a Hardest production car ever built. Its torsional stiffness is 70,000 Nm/degree, while a “regular” supercar reaches 40,000 Nm/degree, the company explains. It also adds that the 440-pound monolith can withstand three times the vehicle’s weight.

Only 150 Nevara will be produced, each powered by 4 motors and 120 kWh, 6960-cell. the battery delivers 1,914 hp and 1,741 lb-ft of torque. Hopefully crashing units doesn’t affect that output tally.