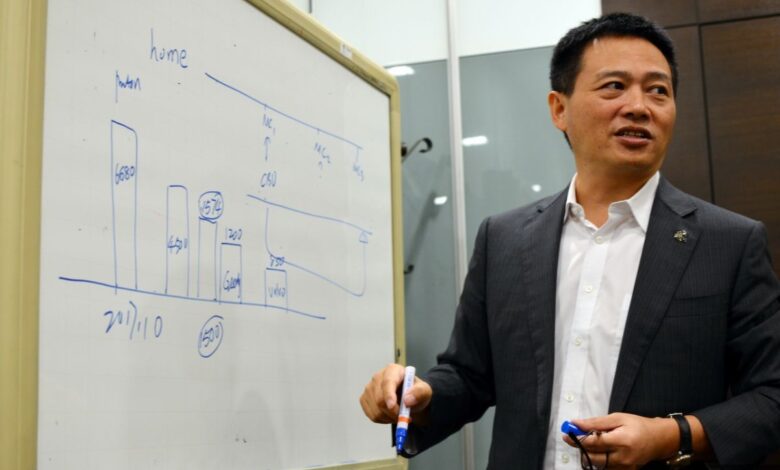

Proton CEO Li Chunrong leads weekly ‘war room’ meetings to tackle spare parts shortage

Protons have experienced dramatic growth over the past few years; That is a fact. Proton is experiencing some growing difficulties in the back of sales, where a lack of parts for accident repairs and scheduled maintenance has caused customer dissatisfaction. It is also a fact, and a fact that The car manufacturer has admitted.

Acknowledging and embracing the problems at hand is the most important first step to solving a problem, and Proton is well aware of its aftermarket woes, which if left unchecked can drive down prices. sales value (haven’t happened yet, Pre-orders are still strong) and cause permanent damage to its reputation.

This seriousness is highlighted by Proton Deputy CEO Roslan Abdullah when paultan.org met him last week to chat about the carmaker’s after-sales issues. It’s not a secret Sales growth is the main focus of Proton and its CEO Li Chunrongbut the head, which the company calls Dr. Li, is currently personally leading the after-sales battle with a ‘war room’.

“We take it very seriously,” said Roslan, who is also a director of Proton Edar.

“We take it seriously, not just at the operational level, but including myself as well as Dr. Li. Currently, Dr. Li actually chairs a weekly meeting, what we call the war room. We spend a minimum of five hours a week just for after-sales. Last week, I think we spent almost 10 hours just doing the aftermarket work,” he revealed.

These ‘war room’ meetings have been going on since January 17. “Not only are they involved in after-sales, but all areas, even procurement, quality and production, no only (those fields) under Proton Edar. Just to make sure suppliers deliver parts and parts from Geely on time,” said Roslan.

That’s a lot of time spent on a problem for individuals tasked with running an automaker. What happens in the war room? Roslan said that fighting the fire took some time. That means managing the complaints they receive and what they read on social media. In addition, Proton is putting in place long-term plans to ensure that the issue of spare parts shortages is addressed.

“For example, we aim to have full stock by April. What we determine by adequate inventory is three months of dealer stock, three months of stock in our warehouse, and stock availability. certain month in stock at our suppliers,” he said.

Earlier this month, Proton officially announced that they have deployed mandatory requirement in which all dealers are required to have at least three months of stock holding out of 22 fast moving parts. This first step also extends to the automaker’s central parts hub. With this request, it is expected that the customer’s waiting time will be reduced.

Here are excerpts from a lengthy conversation with Roslan that delves deeper into Proton’s lack of spare parts. A more detailed story will be coming soon.