More range, power in a smaller package: ZF previews electric vehicle technology

Major supplier ZF has released a concept car based on the Porsche Taycan, built to showcase the next-generation EV powertrain that it will sell to automakers from 2026.

Company – best known for its automatic transmission – its EVbeat concept statement sets the standards for compactness, lightweight design and energy efficiency. That’s important because fitting larger batteries into long-range electric cars is unlikely to be an effective tactic to increase range.

ZF’s ‘EVSys800’ powertrain includes an 800V electrical architecture to enable rapid DC charging, but adds new silicon carbide power electronics, an electronic motor and a newly developed reduction gearbox. develop. Power from the motor is 275kW peak, or 206kW continuous.

The company says the battery-free powertrain weighs 74kg, which is 40kg lighter than ZF’s current 800V series drivetrain when it comes to producing the same output.

A new patented form of electric motor winding saves space and cuts copper use, reducing costs, and features a new cooling method – oil flows directly around the copper rods – capable of capacity allows higher performance in smaller installation spaces.

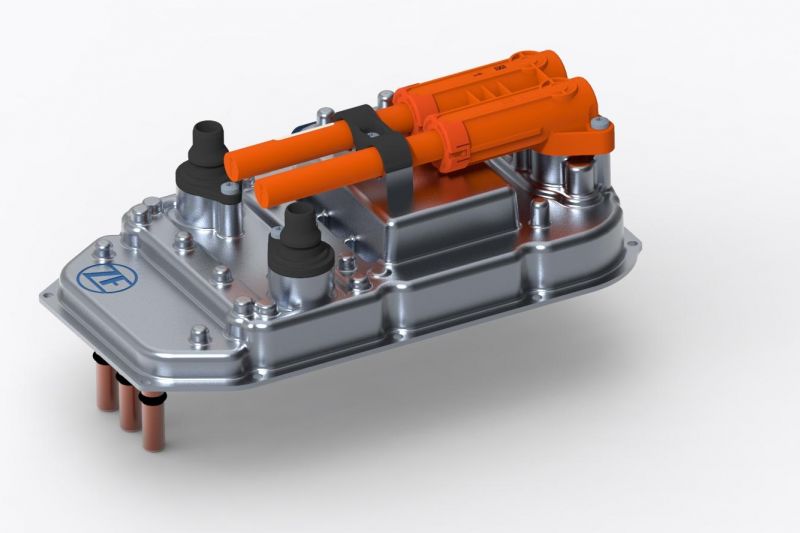

Meanwhile, the inverter has also been “fundamentally redesigned”, with ZF claiming “significant improvements” to things like electromagnetic compatibility and the way power modules are packaged. and capacitors.

The new coaxial reduction gearbox drives the engine through two sets of planetary gears creating the desired final gear ratio and implementing an integrated differential function. This makes available products easier to pack, ZF claims.

“With this system, we were able to perfectly meet the key requirements of our customers – namely efficiency, performance and cost,” said ZF’s head of electric powertrain development, Otmar Scharrer said.

“In terms of torque density, we are at the top of the table when we compare ourselves to electronic powertrains for passenger cars currently on the market. At the same time, we pay special attention to the sustainability aspect of the development process.”

The electric motor operates without heavy rare earths and the thermal management system does not use fluorine-based coolants. Reduced component count and 30% reduction in total system weight are considered double rewards.

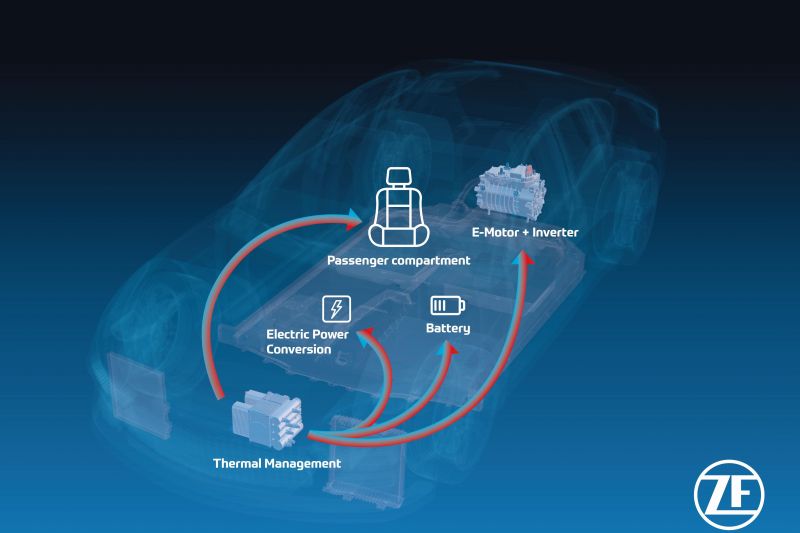

Another area of focus is the thermal management system with three designated circuits, much of which is designed to cut down on the amount of energy sucked out of the battery on cold winter days.

A central unit and software control all thermal processes for the powertrain and passenger compartment, while a propane-based 800V heat pump uses significantly less energy.

Indeed, ZF claims battery life is increased by up to a third in “demanding winter operations”, while at the other end of the spectrum, significantly better cooling performance helps the electronics have higher continuous capacity.

On the software side, ZF has developed its own powertrain coding to connect all vehicle systems together and establish a connection to the cloud.

The powertrain software can also predict optimal operating points from individual driving profiles and prepare the system accordingly. It ‘learns’ the driver’s behavior and can predict probabilities through an AI-based cloud service. Ghostly.

THAN: Inside vendors – ZF