2022 Ford Maverick Hybrid MPG and Suspension Deep Dive

I don’t think I’ve ever been approached more enthusiastically than at a gas pump. No less than three passersby wandering while I was operating the nozzle got stuck on this side 2022 Ford Maverick, their extensive questions included, “Is that mixture? ” “What kind of mileage do you get?” “Is it four-wheel drive?”

“It’s the new hybrid,” I say, but shyly admit that I don’t know the MPG yet because I’m doing a quick recharge of the tank so I can reset the odometer and record its activity. in the next week. I would have said, “Impressive as hell”, if they had wandered after I completed 311.1 miles of driving. The 7.91 gallons I added at the end hit 39.3 mpg, a devastating number vans‘NS EPA Overall rating is 37 mpg.

It gets better. City driving is where hybrids really shine, and really MaverickRated by 42 mpg city and 33 mpg highway. Any combined EPA rating is a weighted average, assuming 55% of mileage will be city driving and 45% will be highways, so it’s great that I recorded the average averages 39.3 mpg with mixed driving that covers 80% of highway driving at 70 mph.

What does this have to do with deep diving by suspension? More than you might think. To answer a passerby’s all-wheel drive question, no Maverick hybrid doesn’t have it. In fact, every hybrid is front-wheel drive and that’s not all. Ford Not only does it remove the rear-wheel drive axle and differential for the hybrid, it has a completely different rear suspension layout than the four-wheel drive models that come with only the 2.0-liter turbocharged engine (and opposite).

My Cyber Orange was loaded for perhaps four or five miles of it. I helped a friend tear down a trade show booth and ship about 400 to 450 pounds of stuff back to his store, where he let me take these pictures. The truck carried this load admirably, with a bit of slack. I was impressed with how smooth and quiet it sucked up Michigan-level mists when it was also empty. Consider price points and energy saving of this machine, they have adjusted this suspension pretty well.

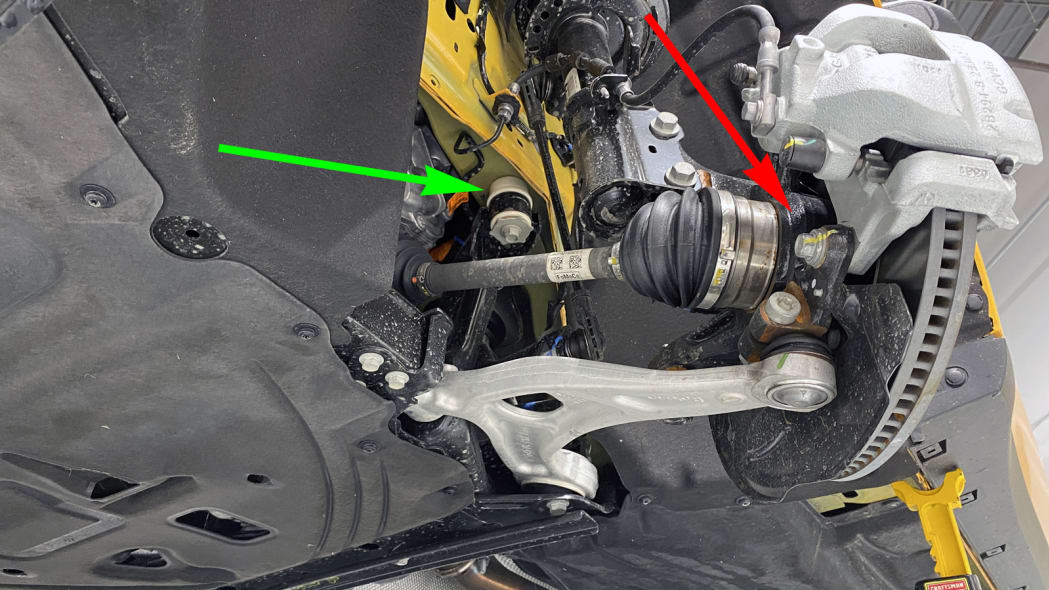

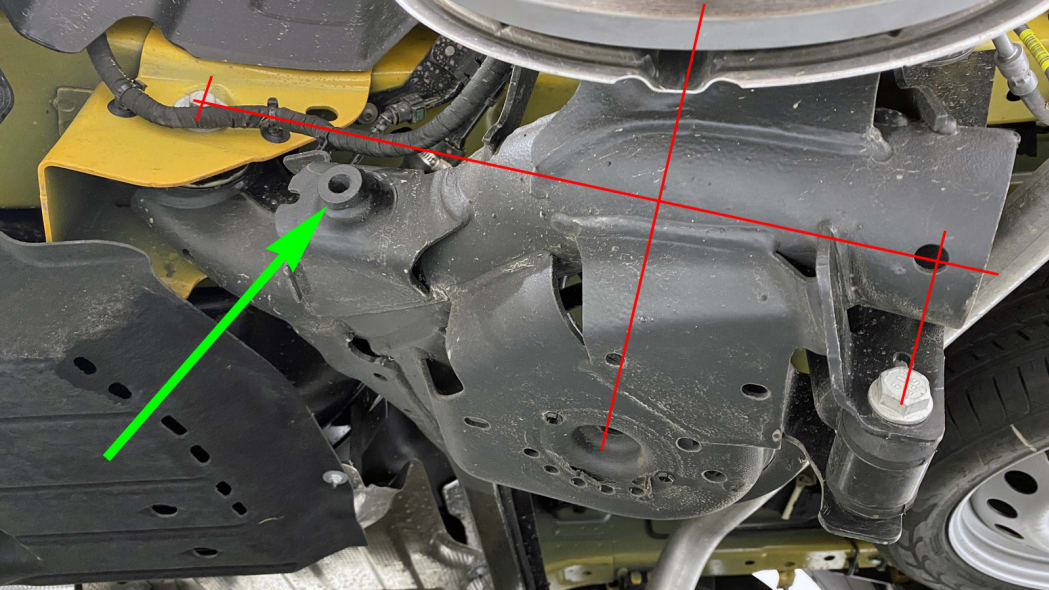

There is nothing groundbreaking going on ahead. It’s a common strut setup that looks very similar to what underlies the Ford Bronco Sport we reviewed a few months ago. As with Bronco Sport, most of the horizontally mounted hybrid powertrain (green arrow) is positioned slightly ahead of the front axle.

This junction (in green) is one of several places where the suspension subframe snaps into the body. The aluminum lower collarbone doesn’t need an arrow because it stands out against the background, but the compact nature of the steel handlebar joint (red) is easy to miss as it blends into the background.

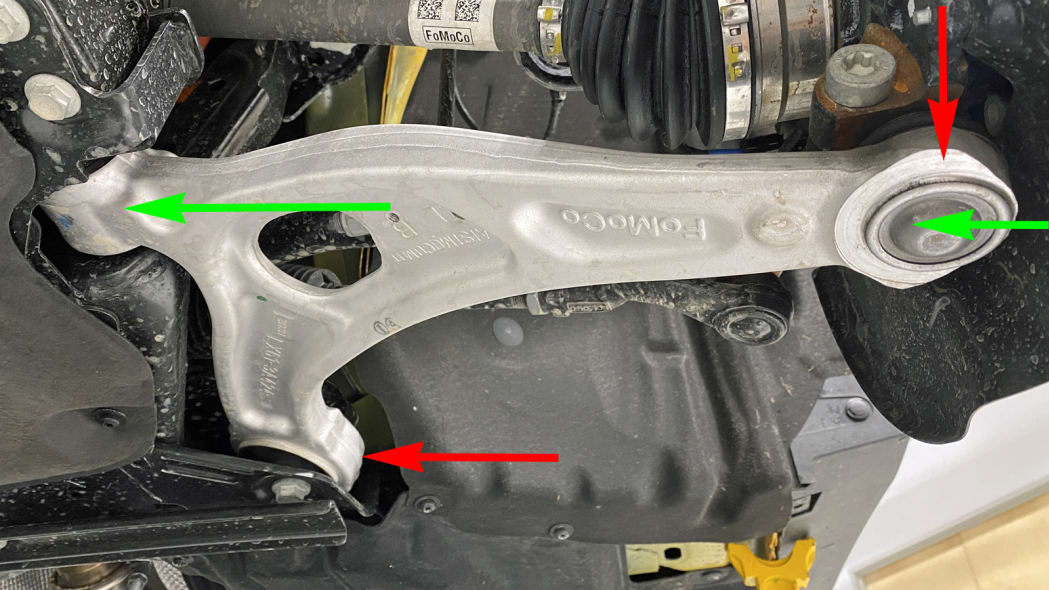

The lower handlebars use an inverted L-shaped design, so named because while side cornering loads (green) are transmitted directly to the chassis via a rigid forward bushing, the component The vertical of the harsh car inlet will rotate 90 degrees and push in at the more massive (red) rear bushing. You can hear engineers refer to “car bushings” in a certain suspension, and in an inverted L-strut arrangement like this one, that’s the layout at the rear.

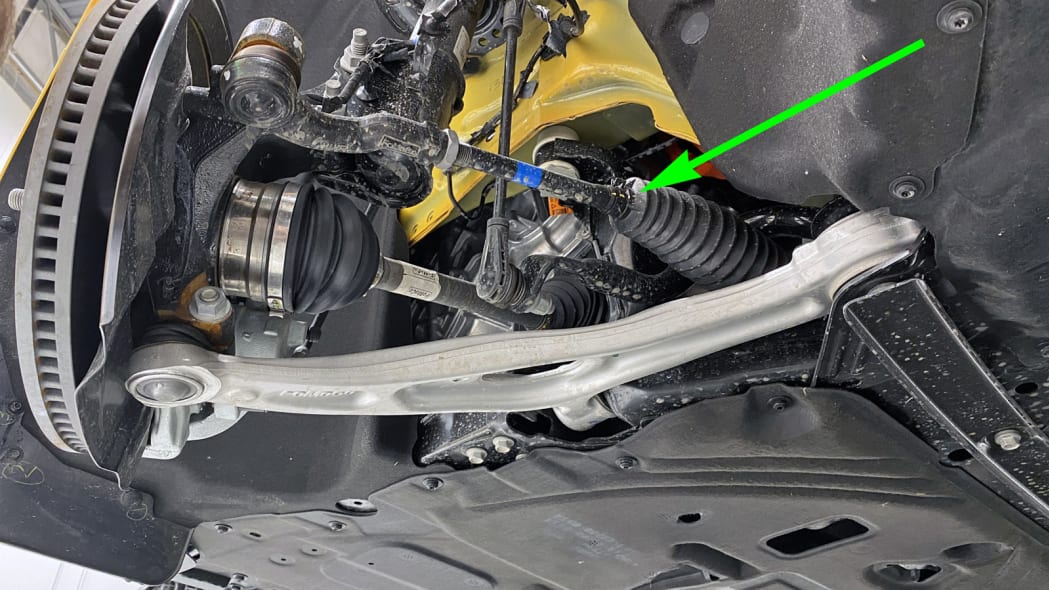

Nearly every horizontal front-wheel drive setup I know of puts the majority of the engine and transmission in front of the front axle, and that means the steering rack (green) can only be rear-mounted and active. behind the steering axle in the so-called “rear orientation”.

The stabilizer bar (green) also extends the Maverick behind the engine, which is why we see its connection link bolted to a tab weld on the rear of the strut housing. This type of strut mounting is known as direct mounting, where the stabilizer link moves up and down in a locking pitch with the wheel in a 1-to-1 motion ratio.

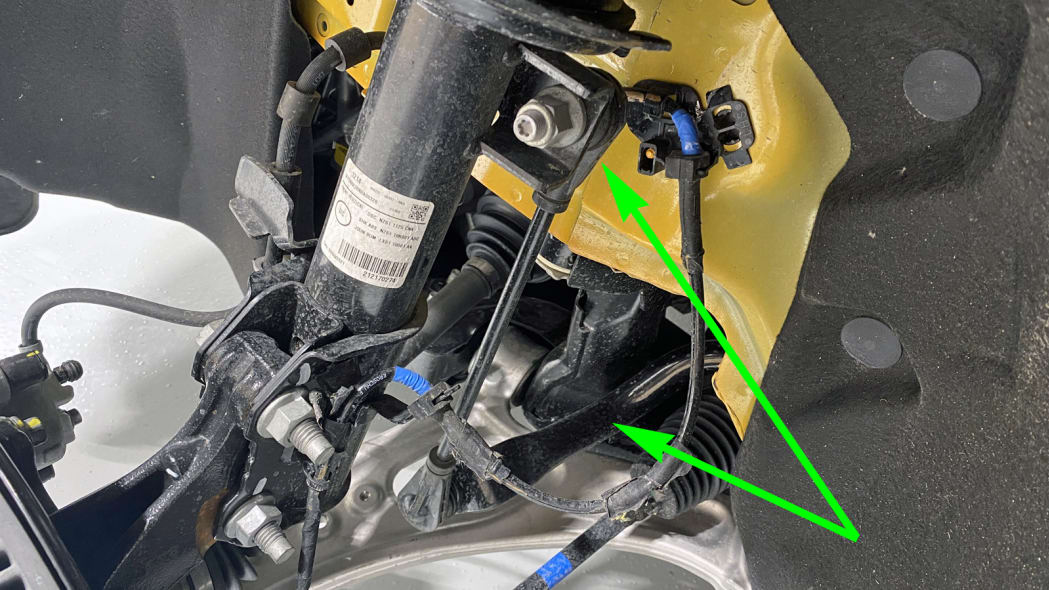

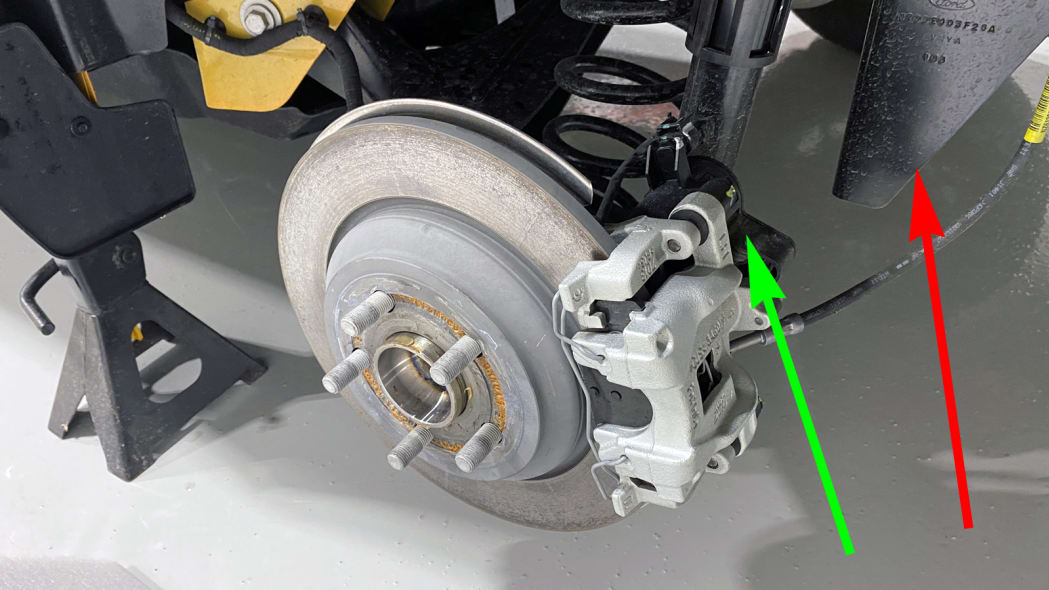

The main driver of hybrid fuel efficiency, especially in the city, is due to the “regenerative” magnetism brake“Through the electric motor/generator buried in the hybrid transmission. The ability to recover brake energy in this way and convert it into electricity for the battery is basically what makes a combo job. This action is still triggered by the brake pedal, but a computer will decide if magnetic regenerative braking or traditional frictional braking will suffice for your brake input, which will then act accordingly.

Thus, this single piston caliper and ventilated rotor are sized as if they were the base brake system, but they won’t be used very often unless you’re in the habit of making short stops and pressing the brakes. The best way to increase your MPG in a hybrid is to look ahead, anticipate slowing down, and apply the brakes gradually so you recover as much braking energy as possible. In fact, the dash of the Maverick hybrid has a pop-up meter to give you instant feedback to help you know where that threshold lies. Pay close attention and you will not only increase your MPG, you will also be able to get 100,000 miles from these brake pads.

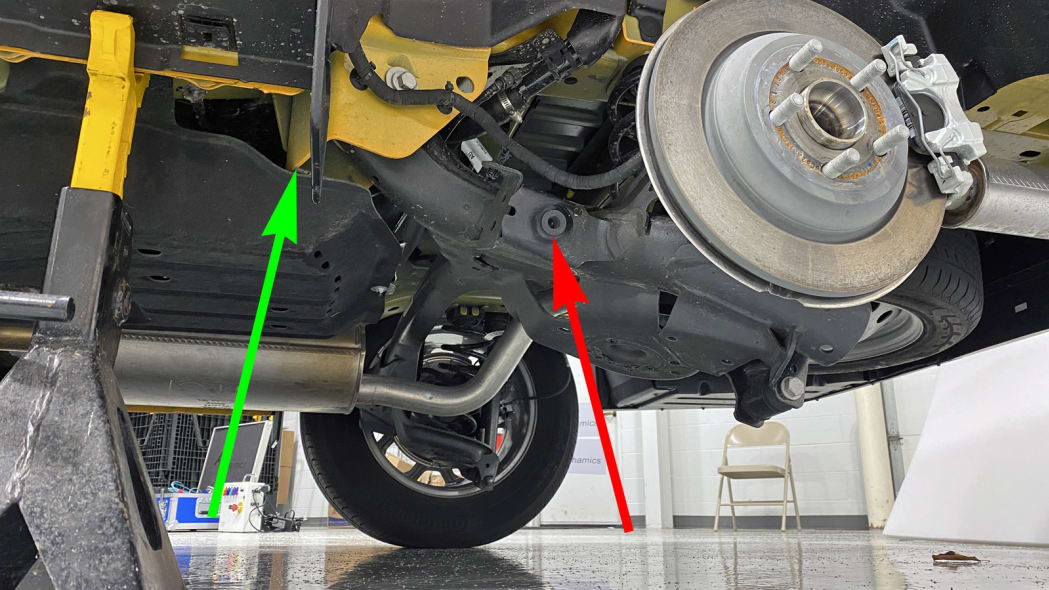

This overall look doesn’t reveal much about the rear suspension of the Maverick hybrid other than that it’s pretty straightforward.

We can now identify this as torsion beam rear suspension, a simple and inexpensive type of semi-independent suspension built around a crossbar (red) extending under the vehicle. to the other side. Why sell independent? The left and right wheels are both fastened to the ends of the same large u-shaped steel structure, but the structure is wide enough that it twists in the middle and allows for some independent movement.

The torsion beam construction bolts to the chassis and rotates around a single point (green) on each side, and the only thing keeping the springs from falling out all the way is the built-in internal stop. rear shock absorber (white. )

Here is a closer look at the proportions of the beam (in green) spanning the truck. Imagine a motorcycle swingarm is 4 feet wider with wheels on the outside of each leg instead of a catch wheel in the middle. Or think of it as a giant stabilizer bar with wheels on either end – that’s basically how it works.

The torsional stiffness of the torsion beam itself is adjusted and optimized during development by fitting an additional stabilizer bar (green) hidden in the open cross-section of the beam.

That additional stabilizer bar (green) is welded in place, and since the wheels are bolted to the flange welded to the girder ends, the roll stiffness motion ratio can only be 1-1. After all, the torsion beam is one big piece.

As for the spring movement ratio, the pocket spring looks slightly forward of the wheel’s axle, so we’ll call it 0.9-1. Meanwhile, the shock absorber is bolted behind the bearing and wheelbase, so it will actually move more than the wheel through a given shock in a 1.2 to 1 motion ratio.

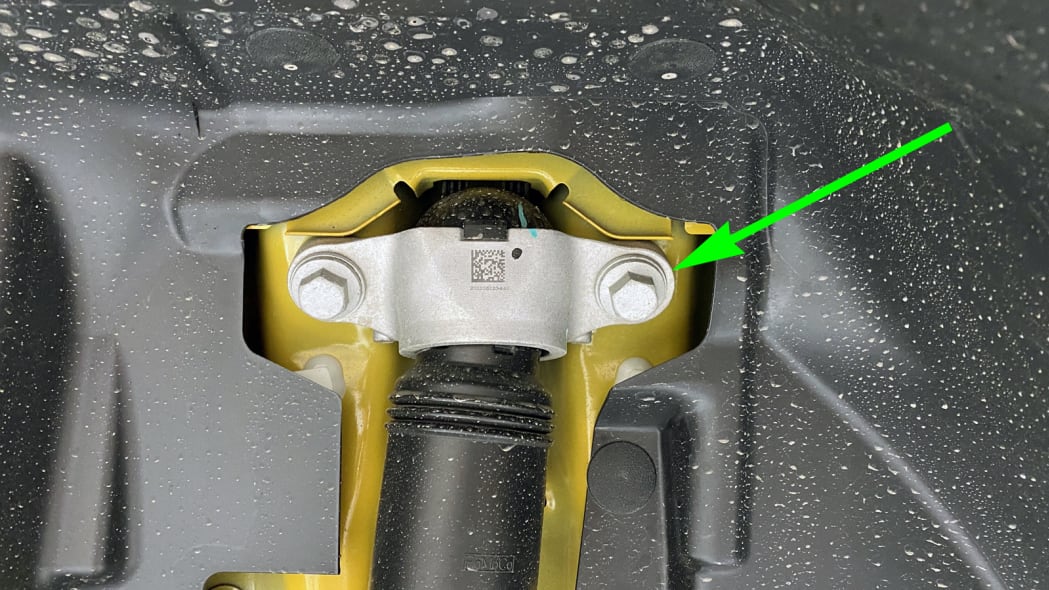

The problem with torsion beam suspensions is that they can produce a rear hum when the outer rear suspension compresses and takes on lateral loads – a bad thing for the outer rear tires when in a deep bend. The situation is complicated because you want a stiff bushing to minimize toe change in such conditions but a soft bushing to absorb the rigors of the ride. One of the ways to combat this is to slant the shaft bushing (green) forward forward.

Here, the inner side of the bushing (green) leans against the outer checkered bushing pocket, creating a ramp that provides the mounting point with forward and backward support when subjected to forces. Into the corner. But the opposite side (red) is more open, so that the bushing can pulse again and absorb the strong impact component from the rear of the impacts on the road. It’s not perfect, but it helps.

However, this one contradictory feature defines the limitations of torsion beam suspension, which is why you won’t see it on anything larger and heavier than the Maverick. But they’re light, cheap, space-saving, and easy to install on the assembly line, which is why it’s used here on the low-cost front-wheel drive Maverick hybrid.

This view gives you an inside look at all the different brackets welded to the torsion beam and we can see the flange (green) to which the caliper and wheel bearings are bolted. .

The upper end of the shock absorber is bolted to the single bed structure from within the wheel, which is why the inner surface of the bed does not need an access plate. The rear bumper suspension is housed in the black plastic trunk we see here.

The Maverick hybrid is light enough for a solid brake rotor to do the job, and its single-piston slide caliper has an electric (green) parking brake actuator hanging at the rear. Meanwhile, that big (red) metal block has no suspension function whatsoever. It is a sled fastening point.

NS Ford Maverick Hybrid XLT roll on 225/65R17 Continent ProContact TX tires mount to 17 x 7 inch aluminum alloy wheels, and this combination weighs in at a neat 49 pounds.

As for the all-wheel-drive, non-hybrid Maverick, its rear suspension will be very similar to the multi-link system we’ve seen under the Bronco Sport, at least in concept. As for the Maverick hybrid suspension we just saw, its simplicity is not surprising considering its extremely low base price. What you can’t see here, though, is how nicely it’s all tuned. It really might be that simple, but it just works.

Related videos: