Tesla’s affordable car, delivery truck teased in master plan

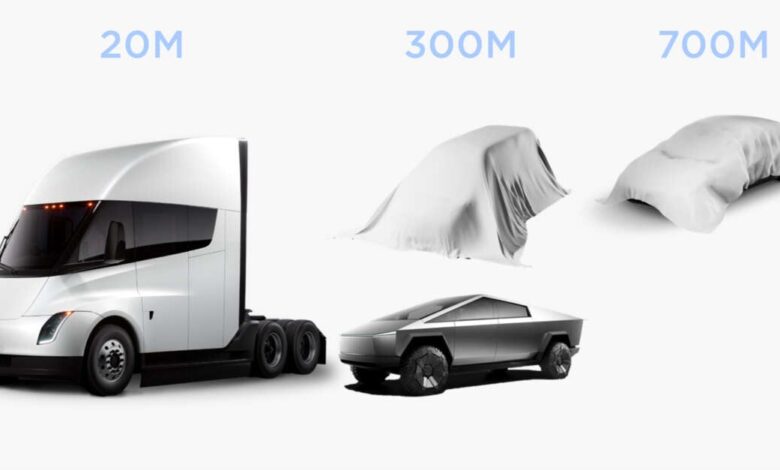

Tesla released Master Plan Part 3, the proposed path towards a sustainable global energy economy through end-user electrification and sustainable electricity production and storage. Here, the American electric vehicle manufacturer has revealed a number of upcoming models that are still shrouded in secrecy.

In the section called ‘Global Electric Vehicle Fleet’, the first one features an MPV silhouette, placed in the same column as the Cybertruck.

The first of two enclosed, MPV-shaped vans could be the EV maker’s upcoming delivery van for commercial applications, however it could also be a cab self-propelled.

Meanwhile, the second model appears to be a smaller car and its projected sales are implied by placing under the heading 700 million units making it a much larger sales model. , and thus potentially a much more affordable model than the Tesla. produced so far, thus excluding Tesla convertible is the second of two future models concealed for the immediate future.

Tesla’s autonomous driving approach shows its application Fully autonomous driving assistance (FSD) software which it rolled out to customer cars – though stopped in February waiting for firmware update – and different from other autonomous vehicle drivers such as roadfocuses on developing systems that do not require human intervention.

Separately, a compact car the size of Honda Fit (Jazz Music) locating below Model Y is in the process of working, report Torque newscites an unnamed internal source from wire.

According to Chinese technology website 36Kr, Tesla aims to produce up to four million units of the new compact model annually from four gigafactories in Texas, Mexico, Berlin, Germany, and Shanghai, China. The report does not mention whether the Model Y compact car is the one shown by Tesla in the illustration.

The website cites Tesla CEO Elon Musk as saying that the Mexican factory will adopt a manufacturing method that assembles a car into six separate parts before combining them into a car, which will improve 30% improvement in space efficiency and 40% reduction in production line area. %, which reduces the production cost of Model Y by 50%.