Toyota’s Pratt is wise to put many eggs in one car basket – Watts Up With That?

Via Duggan Flanagan

July 18, 2024

In a featured conversation with moderator Peter Bryant at the recent RealClearEnergy Future Forum, Toyota chief scientist Gill Pratt said his company’s philosophy is focused primarily on quality of life. From that perspective, he added, the future of the automobile must be a multi-pronged path that respects the diversity of people and the diversity of how they use motor vehicles (see the video above for Pratt’s take).

Toyota, he said, recognizes the difference between decarbonization—the goal—and electrification, the means to get there. That’s why Toyota is building hybrids, electric vehicles (EVs), and internal combustion engines that use hydrogen as fuel instead of gasoline or diesel. He added that in developing countries where electricity is in short supply, low-carbon liquid fuels may be the best option.

Before being recruited by Toyota to lead its research institute, Pratt worked on robotics and neuromorphic computing at the Defense Advanced Research Projects Agency, building machines that could help in disasters and computers that function more like the human brain. There, he says, he learned that technological predictions are often unreliable and that we should expect to be surprised.

Cars today are much more advanced than they were 20 years ago. Today, global positioning systems help guide drivers through both urban and rural traffic; we now have phones and internet in our cars; and today’s onboard computers are sophisticated enough to drive themselves safely with or without passengers.

But we have also concluded that the products of fossil fuel combustion exceed the limits of human tolerance and threaten our future. The “quick fix” of electrifying everything has proven to be a daunting challenge, given the sheer scale of battery-powered electric vehicles needed to replace the 300 million cars in the US and the billion and a half worldwide, most of which run on gasoline or diesel.

To achieve a safe self-driving car, Toyota has taken a multifaceted approach with a focus on saving lives sooner. The company’s approach to decarbonization also focuses on a variety of solutions, including battery electric vehicles, plug-in hybrids, and fuel cell electric vehicles. “We want to provide people around the world from all walks of life with the best tools to tackle the global climate change problem,” Pratt said in the 2021 Toyota Research Institute video.

“Different people,” he said later, “have different circumstances and needs. Some live in areas where the grid is powered by renewable energy; others live in areas that will be powered by fossil fuels for some time. Some have convenient charging stations at home; others live in cities where that is more difficult. Some are wealthy; most are not.”

One benefit of this strategy is more judicious use of available lithium, a key ingredient in today’s EV batteries. Pratt explains that Toyota’s strategy focuses on maximizing the carbon return on investment for each battery cell produced, defined as grams of carbon dioxide saved divided by grams of lithium used.

With the average American commuting 32 miles a day, hauling a battery pack with a range of 320 miles would yield a low carbon ROI. Spreading the same components of these large EV batteries into multiple hybrids would multiply the carbon ROI for these expensive battery components. A battery EV uses about 90 times more lithium than a hybrid. On the other hand, braking power increases the efficiency of battery EVs in city traffic.

Toyota has found that hybrids and plug-in hybrids have similar lifetime carbon emissions to battery electric vehicles at a lower cost to consumers. Full electric vehicles may still be a better choice wherever there are plenty of fast charging options and enough affordable electric capacity.

But that’s hardly true in the developing world, or even in most parts of the United States today. That’s one reason Toyota is focusing on hydrogen-powered vehicles, which also don’t emit carbon dioxide from their tailpipes. Although hydrogen is a gas that must be cooled to near absolute zero or compressed to be used in a motor vehicle, supplies are plentiful. The petrochemical industry alone produces enough hydrogen to fuel millions of vehicles.

Hydrogen has been used in internal combustion engines for racing cars, but Toyota believes its sweet spot could be in 18-wheelers, tanks, cranes and other large vehicles that would otherwise require large electric batteries that add weight and reduce payload capacity. While Toyota is expanding its European operations through Hydrogen Factory Europe, it is applying fuel cell technology to buses and trucks, rail, sea and river transport, and even basic electricity generation.

ONE recent posts Note that Toyota’s hydrogen internal combustion engines offer excellent performance while being efficient in their engine features. These engines can deliver up to 400 horsepower, comparable to many Atkinson cycle piston gasoline engines, and can achieve thermal efficiencies of up to 45%, comparable to the best diesel engines. The only exhaust from these engines is clean water vapor.

Other recent posts Toyota’s hydrogen fuel cell system involves a chemical reaction between hydrogen stored on board the vehicle and oxygen from the surrounding environment to generate electricity for an electric motor without the need for heavy lithium-ion batteries used in battery-powered electric vehicles, it explained.

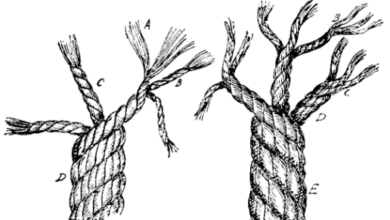

Pratt compares Toyota’s decision to pursue a multipronged approach to the future of the auto industry to the old debate between VHS and Beta. Those who put all their eggs in the Beta basket went bankrupt because VHS proved more consumer-friendly than the technologically superior Beta. But he says that in the future of the auto universe, battery electric, hybrid, plug-in hybrid, and hydrogen-powered vehicles could all play a role.

The bottom line, however, is that the poor and middle classes around the world will continue to rely on gasoline and diesel internal combustion engines until these newer technologies can produce vehicles they can afford to buy and maintain, and until fuel supplies (including abundant electricity) are also available at affordable prices.

While gasoline fuel lines and electric charging cables are the same size, today’s fuel lines deliver ten times the power of electric chargers in a much shorter time frame. Multiply the charging time by the time it takes to refuel with liquid fuel and you begin to see the scale of the challenge.

Texas-based Buc-ee’s just opened its largest station yet, with 120 pumps on a 75,000-square-foot lot. They would have to have 1,200 of today’s best chargers, which would cover about 750,000 square feet, to service the same number of electric vehicles they do now.

With 80% of EV chargers in the US now being slow chargers, the transition even in developed countries may be happening more slowly than politicians and bureaucrats claim.

Duggan Flanagan ([email protected]) is a senior policy analyst at the Committee for a Building Tomorrow, who writes on a variety of public policy issues.

This article was originally published by RealClearEnergy and syndicated via RealClearWire.