New optical fabrication method using liquid polymers for faster and cheaper custom lenses: Digital photography review

|

Researchers at Technion – Israel Institute of Technology Yes developed a ‘faster, cheaper method to manufacture custom optical components’ for applications including ‘corrective lenses, augmented reality, autonomous vehicles, medical imaging and astronomy .’ As Do-it-yourself photo shoot observe, it is not unreasonable to think that the new method of making lenses could be used for photographic lenses, at least during development and prototyping.

Optical lenses come in many different shapes and sizes. The more complex a lens is, the more difficult and expensive it is to develop and manufacture. Specialized equipment is required. At the Technion Institute of Technology – Israel, the research team has developed a method of forming a curable liquid polymer. This method can be used to fabricate large optics, which has proven challenging for other similar methods.

Lead researcher Moran Bercovici from the Technion Institute of Technology – Israel said: “Our method to generate free-form optics achieves an extremely smooth surface and can be performed using mechanical equipment. copies can be found in most laboratories. ‘This makes the technology very accessible, even in low resource settings.’

|

| Lens manufacturing. Image supplier: Technion – Israel Institute of Technology |

Bercovici and colleagues published search in Optica, and it shows that this technique can be used to fabricate free-form optical components with sub-nanometer roughness in just a few minutes. It is even faster than other prototyping methods, such as 3D printing.

Omer Luria, a contributor to the research paper, said, ‘Currently, optical engineers pay tens of thousands of dollars for specially designed free-form components and wait months for them to arrive. Our technology is poised to radically reduce both the waiting time and cost of complex optical prototypes, which can accelerate the development of new optical designs. ‘

|

| The team used their method to create a variety of free-form optics, including lenses up to 200mm in size. Image supplier: Technion – Israel Institute of Technology |

Researchers began working on the new method after learning about 2.5 billion people worldwide who need corrective lenses but lack access. Valeri Frumkin, who first developed the method in Bercovici’s lab, said: ‘We set out to find a simple way to fabricate high-quality optical components that don’t rely on a process. mechanical processing or complex and expensive infrastructure.’ The team then realized that the method could be used for much more complex optical terrains, which are traditionally extremely expensive and require specialized equipment to generate. out promptly.

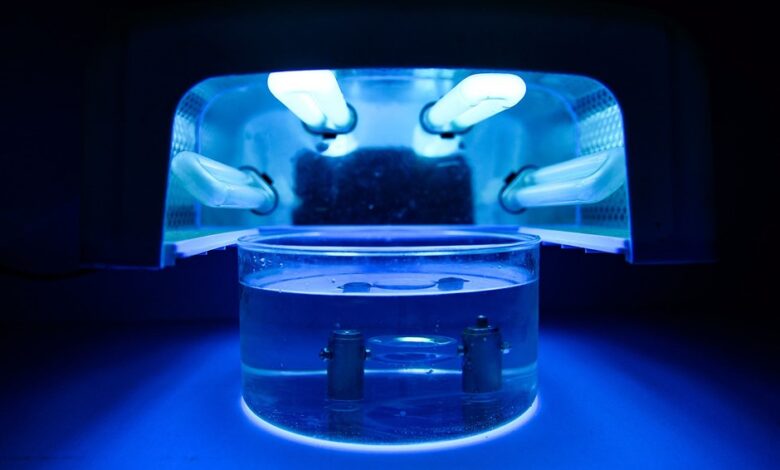

The main challenge of making optics by curing liquid polymers is that when you increase the size of the optics by about 2mm, gravity will overcome the surface forces and the liquid will be flat. To overcome this challenge, the team developed a way of making lenses using liquid polymers submerged in another liquid. Floating forces work against gravity, allowing surface tension to do its job.

|

| From left to right, Mor Elgarisi, Professor Moran Bercovici and Omer Luria. Image supplier: Technion – Israel Institute of Technology |

With gravity treated, the team was able to create smooth optical surfaces. Once you have created the required topography of the optical element, using UV exposure or other methods, treat the liquid polymer. To date, the team has successfully fabricated various optical lens shapes and sizes, with sizes up to 200mm and tree-like shapes.

Lead author of the study, Mor Elgarisi, said, ‘We have identified a multitude of optical landforms that can be fabricated using our method. This method can be used to fabricate components of any size and because the liquid surface is naturally smooth, no polishing is required. This method is also compatible with any liquid that can be solidified and has the advantage of not producing any waste. ‘

|

| Mor Elgarisi. Image supplier: Technion – Israel Institute of Technology |

It’s easy to envision possible applications for such technology. In addition to improving people’s lives by making corrected optics more accessible, this approach could also enable laboratories and small businesses to operate more efficiently, thereby accelerating innovation. new. Perhaps this method could even be used to model camera lenses.