LG Chem plans to build $3 billion EV battery materials plant in Tennessee

LG Chem announced Tuesday that it is planning to build a giant cathode materials plant in Tennessee that will support domestic U.S. electric vehicle battery production.

According to LG, the plant will be the largest of its kind in the US, and at full capacity it will be able to produce 120,000 tons of cathode battery material—enough to produce batteries for 1.2 million vehicles. electricity annually, assuming a 310-mile range per vehicle.

LG Chem says the new location will play an important role in growing its battery materials business fivefold by 2027, compared with 2022 levels. It will also help automakers buy US-made batteries are subject to pending raw material sourcing rules in the Inflation Recovery Act. That compliance promotion has been supplemented recently with a long list of federally funded battery supply chain projects across 12 states.

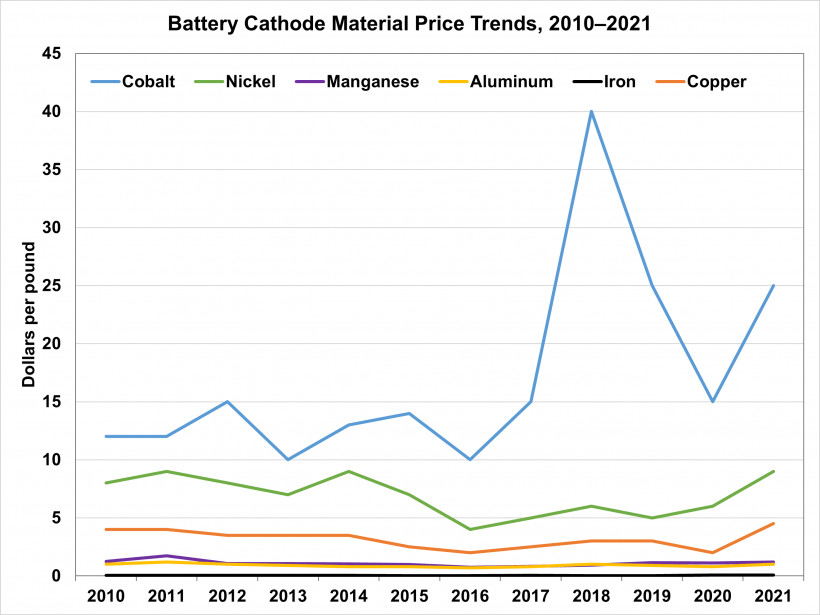

Meanwhile, prices for cathode materials have surged, largely due to increased demand for them as cell manufacturers ramp up production.

Electric vehicle battery cathode material price trend, 2010-2021 – US DOE

Tennessee Governor Bill Lee on Monday, according to Tennesseecalled the LG Chem factory “the largest single foreign direct investment in the history of the state.”

LG Chem says the facility will manufacture NCMA cathode materials (nickel, cobalt, manganese, aluminum) for next-generation batteries with improved capacity and stability — extending battery capacity and EV life . The facility will create more than 850 jobs, but the company says it plans to automate the entire manufacturing process and establish “a quality control and analysis system that will be the standard for all other cathode plants in the world”.

That serves as a reminder that another LG company, LG Electronics paid GM $1.9 billion because of a battery manufacturing problem that resulted in the recall of every Chevrolet Bolt EV produced, plus extensive battery pack replacement in the recall. That problem was attributed to two unrelated manufacturing defects that needed to occur simultaneously, and while unrelated to the cathode material this plant would produce, it was a reminder of the importance of quality control.

Concept drawing of the Ultium Cells plant in Tennessee

The company did not say where the cathode material will be sourced. General Motors announced in July that it has “contractual guarantee” of all battery raw materials to meet the production of 1 million electric vehicles in North America by 2025, although it is unclear if this will be included in that number. The Ultium Cells LLC joint venture battery plants in Tennessee and Ohio will be among the four Generating cells for GM EVs. Meanwhile, Honda and LG Energy Solution have committed to invest $4.4 billion in a joint venture battery plant in Ohio to Future Honda EVand LG Energy Solution and Stellantis are collaborating on a $4.1 billion investment battery factory in canada.

LG says the facility will run on 100% renewable energy. According to the Tennessean, the site’s access to energy by the Tennessee Valley Authority played a key role in the decision.

The plant will begin mass production by the end of 2025, while the construction of the plant will begin in the first quarter of 2023.