Better range than weight with lithium-sulfur battery technology?

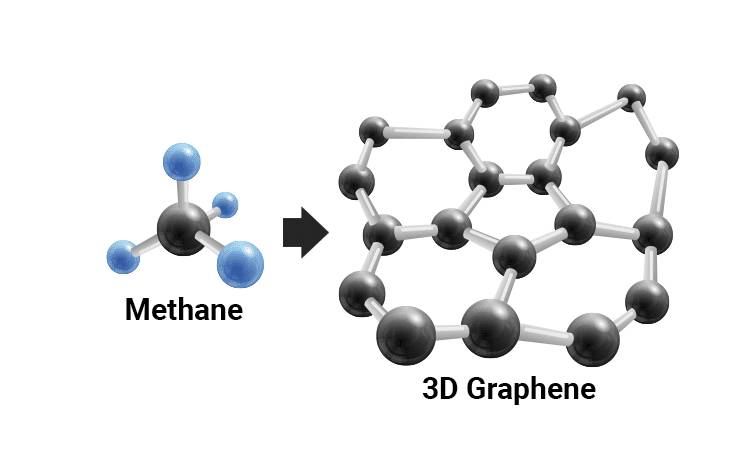

Ask the futurists what materials are capable of making our lives better in every way, and odds are the resulting shortlist will include graphene.

Graphene has become a buzzword for startups in many fields, and it takes center stage in Lyten’s lithium-sulfur EV batteries.

A 300 million euro ($320 million) investment from Stellantis Ventures announced Thursday will allow Stellantis and Lyten to develop solutions alongside these batteries plus additional technology from the startup. in California.

It also claims some serious supply chain advantages and environmental benefits. The companies say Lyten batteries have “a roadmap to achieving the lowest-emissions EV batteries on the global market.”

Stellantis and Lyten – Graphene 3D

According to Keith Norman, Lyten’s director of sustainability, Lyten is currently citing 6% lower carbon emissions in the battery manufacturing process than NMC batteries, and they are working on a plan to reduce that to neutral. carbon.

Lithium-sulfur batteries have long been considered a potentially potent chemist, but there are real-world barriers around life cycle, or degradation, as well as manufacturability. Back at the beginning of the last decade, experts considered lithium-sulfur battery technology to be become commercially viable around 2030and if all goes well, Lyten’s technology could lead the way.

Looking back, Australian researchers in 2020 reported that they saw potential double EV range with lithium-sulfur batteries, but they face low lifecycle problems. Other researchers have successfully introduced a nano-manganese composite sheet to control this unwanted “transit” behavior, but that poses production problems. Researchers at DOE’s Lawrence Berkeley National Laboratory have overcome this problem with a “sulfur-graphene nanocomposite cathode,” but manufacturing capabilities there also seem to stand in the way.

Lyten 3D graphene illustration

Why lithium-sulfur can work this time

Lyten claims to be “the pioneer of the tunable 3D graphene metamaterial,” and the company says that’s what makes lithium-sulfur battery chemistry possible.

For lithium-ion batteries, graphene helps hold the sulfur atoms in place and prevents their movement during charging and discharging. Second, it helps to enable greater energy density, simply through 3D textures.

To turn graphene from a flat sheet of carbon atoms into something useful here, it uses “patent-protected reactor technology” to convert that planar structure into a “shape and structure.” three-dimensional carbon”—basically taking a piece of paper and crumpling it. . According to Norman, that increases reactivity to greater degrees and allows the company to tailor materials to the properties it needs.

Lyten claims that its chemistry delivers 60% lower carbon emissions than today’s lithium-ion cells. The company says it can provide more than twice the energy density of lithium-ion cells,

The company also says that it can produce 3D graphene in a carbon negative manner on a large scale, and with all the rest of the battery considered, it could yield a “world-leading carbon footprint.” .

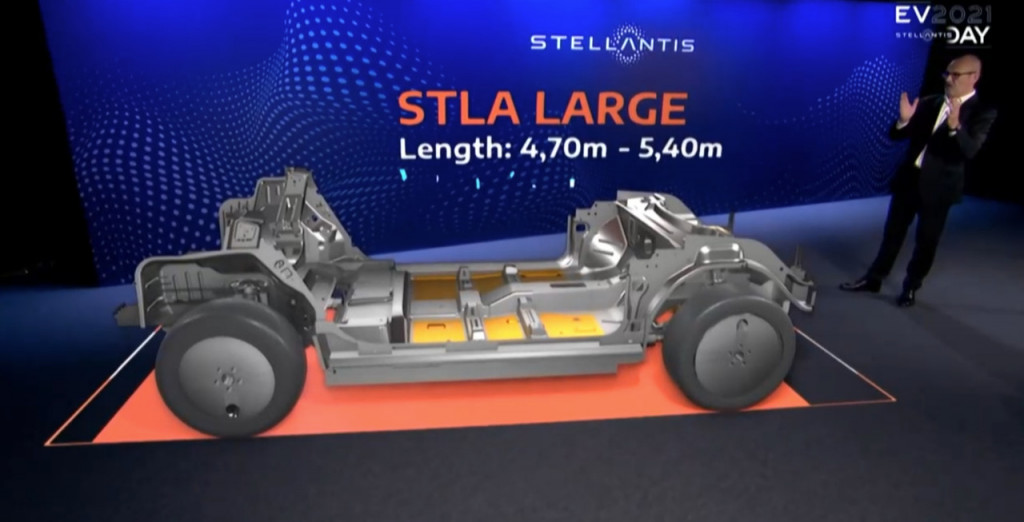

STLA Large Platform – Stellantis EVs

Electric vehicle battery technology can go global

It also says the technology is great for global rollout — partly because of its simplified bill of materials.

As weird as 3D graphene sounds, these lithium-sulfur batteries don’t need nickel, cobalt or manganese for their cathode, and that puts a huge burden on automakers and battery manufacturers. in the procurement of metals and minerals.

Lyten makes graphene from natural gas (methane), in a process they say can be carbon-negative (because it produces hydrogen as a by-product). That natural gas is readily available. So is sulfur, as a by-product of the mining industry. That simplifies supply chains and removes some of the geopolitical risk. Meanwhile, investment in lithium is quite dispersed globally, the company said.

Because of those lower costs, Lyten believes it has “a chemical battery for the masses,” as Norman put it — especially when you consider that, with the same capacity, it can reduce vehicle weight. electricity.

Cylindrical, vesicle and prismatic cell formats

Cylindrical cells – Lyten

Lyten vesicle cells

Lyten prismatic cells

Lyten is also looking at a range of form factors that have been created by big battery players like Panasonic or Samsung SDI, leading with cylindrical cells in the popular 18650 format, then including pocket cells and finally perhaps a prism. As a result, they will be able to be fitted in all sorts of applications—including aerospace and last-mile delivery.

Furthermore, it can be manufactured on the same equipment as existing nickel-based cell lines, the company said.

Will not require new EV battery factories

CEO and co-founder Dan Cook said: “We were able to develop our lithium-sulfur solution to be essentially manufacturable on existing production lines, with some very modest modifications. “We estimate somewhere in the vicinity of about 10 to 15 percent of the direct cost of the production line itself to make minor modifications to handle the lithium-sulfur architecture.”

Lyten just opened a lithium-sulfur battery pilot line in San Jose and will soon deliver the batteries to customers for quality testing and evaluation. That line’s goal is to produce about 200,000 cells a year and test equipment and manufacturing processes, but it hopes to set up a gigawatt-scale line to accelerate EV adoption in the second half. of the decade.

Cook said that the company is initially looking to roll out its technology in the US, then Europe and beyond as the company grows.

Besides the battery, Lyten is also working with Stellantis on a new generation of sensors and using its graphene to create lightweight composites that could help reduce the vehicle’s weight.

The investment in Lyten is fully part of Stallantis’ Dare Forward 2030 strategic plan and its goals cut CO2 in half by 2030and zero by 2038. The Series A round is $160 million, while Stellantis is an important part of the Series C round.

Stellantis targets zero carbon emissions by 2038

Production after the 2020s?

Stellantis is looking at the second half of this decade to incorporate batteries into its electric vehicle platforms.

Lyten says that it has achieved a density equal to and higher than lithium-ion, but over its life cycle it is still a work in progress, on a quarterly basis, with Stellantis and the companies agreeing that it is where work needs to be done. With US and European Union regulators likely to step in this decade over battery degradation and longevity, a solution is needed before the technology is commercially available. chemical.

Is this the future of ubiquitous battery technology for electric vehicles? There’s no knowledge that doesn’t push it further toward production, and it could potentially surpass lithium-ion as we know it.